|

|

|

|

| ||

|

|

|

Breeding program management |

| ||

|

|

|

Breeding for grain quality |

| ||

|

|

|

|

| ||

|

|

|

Introduction

Yield is the most noticeable characteristic to farmers while the crop is in the ground, but when the product of the crop, the milled rice, reaches the market, quality becomes the key determinant of its sale-ability. Thus breeders are mandated to develop germplasm of high quality that suits the particular needs of the market being targeted.

There are several defined classes of rice, based on the physical appearance of the milled rice, the cooking properties and the aroma of the rice. The traits of grain quality are common to every market, but the metric of the trait is not. For example, the trait of texture is common to all markets, but the metric, softness to hardness, depends on the market. Thus quality evaluation programs should go hand-in-hand with breeding programs, and all quality evaluation programs should have the capacity to measure at least the basic traits.

Technology is leaping ahead in the field of quality evaluation, both in terms of instrument capability and genetic and biochemical research that delivers directly to quality evaluation programs. Such research is allowing new methods to be developed that describe the trait directly and give the metric of that trait. Evaluation of quality at particular times in the breeding program enhances the capacity of rice breeders to select or discard for that trait usefully.

|

| ||

|

|

|

|

| ||

|

|

|

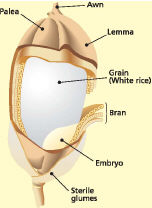

1. What are the traits of physical quality of grain?

|

| ||

|

|

|

The length and width of a rice grain are important attributes that determine the class of the rice. There are three main classes of rice, based on grain length: short, medium and long. In terms of width, Arborio styles are generally the widest, followed by short, medium and long. The ratio of the length and the width is used internationally to describe the shape and class of the variety. The other important aspect of length and width is uniformity – all the grains in one sample must look the same.

Grain weight provides information about the size and density of the grain. Grains of different density mill differently, and are likely to retain moisture differently and cook differently. Uniform grain weight is important for consistent grain quality.

|

| ||

|

|

|

Head Rice Yield is the weight of whole white rice grains remaining after milling, as a percentage of the total weight of the paddy.

Breakage of grain during milling reduces the percentage of whole grain and it can be due to a number of factors. Chalky grains are softer than translucent grains and are more likely to break during milling. Grains that are cracked, either from moisture cycles in the field or rough handling are also likely to break during milling. Head rice yield is often the most important quality parameter to millers since they the head rice yield is generally linked to the payment they receive.

|

| ||

|

|

|

The whiteness and translucence of rice is important. The whiteness ranges from white to yellow. Yellowness occurs because of aging or higher protein content. The higher protein content changes the cooking properties of rice, particularly increasing the propensity of the rice to undergo retrogradation – cooling on cooking.

Translucence relates to the degree of crystallinity of the starch – a function of the structure and packaging of the amylopectin molecules, and to the ability of the light to be refracted without interfering with protein bodies. High protein detracts from quality.

|

| ||

|

|

|

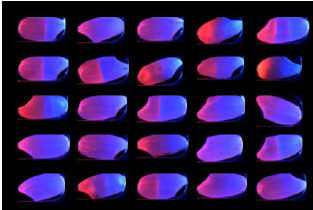

Chalk is the opaque area in the rice grain and is undesirable in almost every market. Chalky areas occur because of malformed starch granules with air spaces between them. Chalky areas cook differently from translucent areas, but only a very clever palate could detect the difference. There are small differences in the solubility of the starch and the gelatinization temperature of the chalky and translucent areas, but research has yet to discover why.

Grains containing different amounts of chalk

|

| ||

|

|

|

In some seasons, cracking of the rice grain is a significant problem. Most cracking occurs in the field and seems to be related to changes in grain moisture or to moisture cycles after the rice matures. Hot sunny days that dry the grain are commonly followed by humid or dewy nights that wet the grain. The changes in grain moisture over a 24-hour period can lead to cracking. Cracking may also result from rain on dry grain and storage of grain with variable moisture levels.

Rough handling of grain during harvest operations and during drying and processing will also cause the grain to crack.

Cracking decreases head rice yield because cracked grains often break during milling. Most markets require whole or unbroken grain, therefore cracked grain can reduce payments received by the grower and the miller.

Cracking also decreases the cooking quality of the grain. Grains that are cracked but remain intact during milling are deemed visually undesirable. Further, during cooking the starch leaches out of cracked grain and collects as a sticky layer on the bottom of the rice cooker. If rice is cooked by the rapid boil technique, the starch leaches from the rice into the cooking water.

Cracks in grain an be detected by using red and blue light.

|

| ||

|

|

|

|

| ||

|

|

|

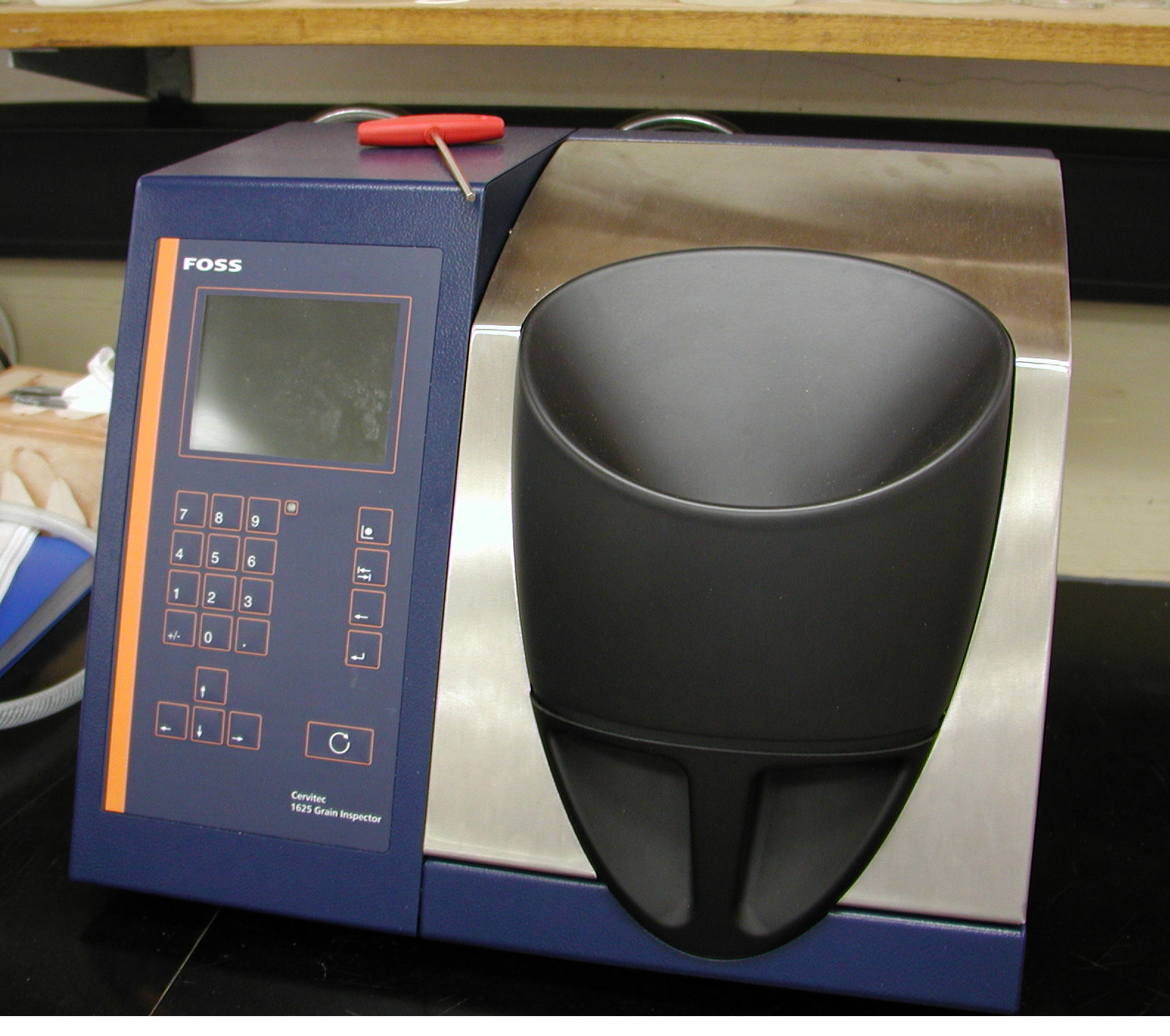

The physical parameters of quality (except colour) can be measured objectively and instrumentally by using a FOSS Cervitec. This machine uses Artificial Neural Networks to ‘learn’ the quality traits of white and brown rice.

The FOSS Cervitec is used at IRRI to produce data about the length, width, chalk and cracks of grain, as well as about its percentage of head rice yield. |

| ||

|

|

|

|

| ||

|

|

|

2. What are the cooking and eating characteristics of rice?

Cooking and eating characteristics of rice are determined by a combination of objective and subjective methods. |

| ||

|

|

|

Amylose content strongly influences the cooking and eating characteristics of rice. Rice with a high amylose content (25-30%) tends to cook firm and dry, whereas rice with a intermediate amylose content (20-25%) tends to be softer and stickier and rice with a low amylose content (<20%) is generally quite soft and sticky. Waxy rice has a zero amylose content and is often referred to as sticky rice. Japonica rice tends to be low amylose, tropical japonica tends to be intermediate or high and Indica rices fall into all the amylose classes.

During the cooking process, the starch granules in the grain expand and amylose leaches from them. As the cooked rice cools, the leached amylose chains line up, lock together and form a gel. In theory, the higher the amylose content of rice, the firmer the cooked grain of rice will be. Amylose is also responsible for the way that rice hardens on cooling. When rice cools to room temperature or beyond, the chains of amylose crystallise. This phenomenon is called retrogradation. Retrogradation is also related to proteins. The gel seems to be strengthened by proteins.

Amylose content is important because firmness and stickiness are two properties of cooked rice that influence consumer preference for, and use of different classes of rice.

Amylose content has traditionally been assessed by chemical analysis of the rice but technology has produced non-destructive methods using the NIR and the visible regions of the spectrum. Recently too, a microsatellite marker has been discovered in the flanking region of the GBSS gene and the polymorphism relates to the amylose class and the market type. Fairly rapid throughput methods have been developed for analysis of the microsatellite in each rice line.

|

| ||

|

|

|

Gelatinisation temperature is the temperature at which the starch in rice begins the process of cooking. At this point the starch granules take in water and lose their crystalline nature, a change that is irreversible. Rice starch usually gelatinises between 65°C and 85°C.

Rice with a gelatinisation temperature at the lower end of the range often cooks to a softer texture and retrogrades less than rice with a gelatinisation temperature at the upper end of the range.

Gelatinisation is often measured by the alkali spreading method. However technology has improved the measurement of this trait too. Differential scanning calorimetry gives the actual temperature of gelatinization and the energy required for the particular rice to pass through that transition.

|

| ||

|

|

|

Viscosity is a characteristic that indicates some of the cooking properties of rice. The cooking properties of rice are primarily measured by Rapid Visco Analysis (RVA), which mimics the process of cooking and monitors the changes to a slurry of rice flour and water, during the test. The slurry is stirred constantly with a paddle and heated. Viscosity is measured as the resistance of the slurry to the paddle. As the temperature of the slurry increases, the starch granules begin to take in water and swell. The slurry thickens and viscosity begins to increase. When the temperature reaches 95°C it is held there and the starch granules lose their structure and viscosity decreases. The slurry is cooled to 50°C, which is below the gelatinisation temperature, and the amylose chains line up, join together and form a gel, and the viscosity increases again. Viscosity curves are a useful breeding tool because the shape of the curve is unique to each class of rice. The drawback though, is that it can only be carried out during the later stages of germplasm development, when there is sufficient seed for a test milling.

Starch granule (as seen through microscope)

|

| ||

|

|

|

Texture describes what we might experience in our mouths when eating rice: initial mouthfeel, hardness, adhesiveness, cohesiveness, springiness, resilience, gumminess and chewiness. These characteristics are generally measured by a sensory panel, a group of people who are very experienced in determining and describing the texture of rice. Rice research and development programs in Louisiana and Arkansas, in the USA, are attempting to identify instrumental methods that correlate well with scores reported by sensory panels for the different textural characters.

|

| ||

|

|

|

Basmati and jasmine are classes of fragrant style rice. Fragrant rice contains particular compounds that give the rice flavour. Otherwise, slightly perceptible changes in flavour of all rice classes can be caused by aging, storage, the depth of milling (i.e. the amount of polishing), the local environment and probably a number of other things.

Flavour in fragrant rice is produced by volatile compounds, many of which are volatilised during cooking to produce an aroma. The aroma of cooking rice may be described as hay-like/musty, popcorn, corn, alfalfa-grassy-green bean, dairy, sweet aromatic (fairy floss, caramel), grassy, vanilla, sewer, animal, metallic and floral. Environmental conditions can cause a lot of the variation seen in aroma. Aroma is measured by simply sniffing the rice. Otherwise the peaks can be quantified by Gas Chromatography. |

| ||

|

|

|

|

| ||

Next lesson |

|

In the next lesson, you will learn about hybrid rice and seed. |

| ||

|

|

|

|

|

.gif)